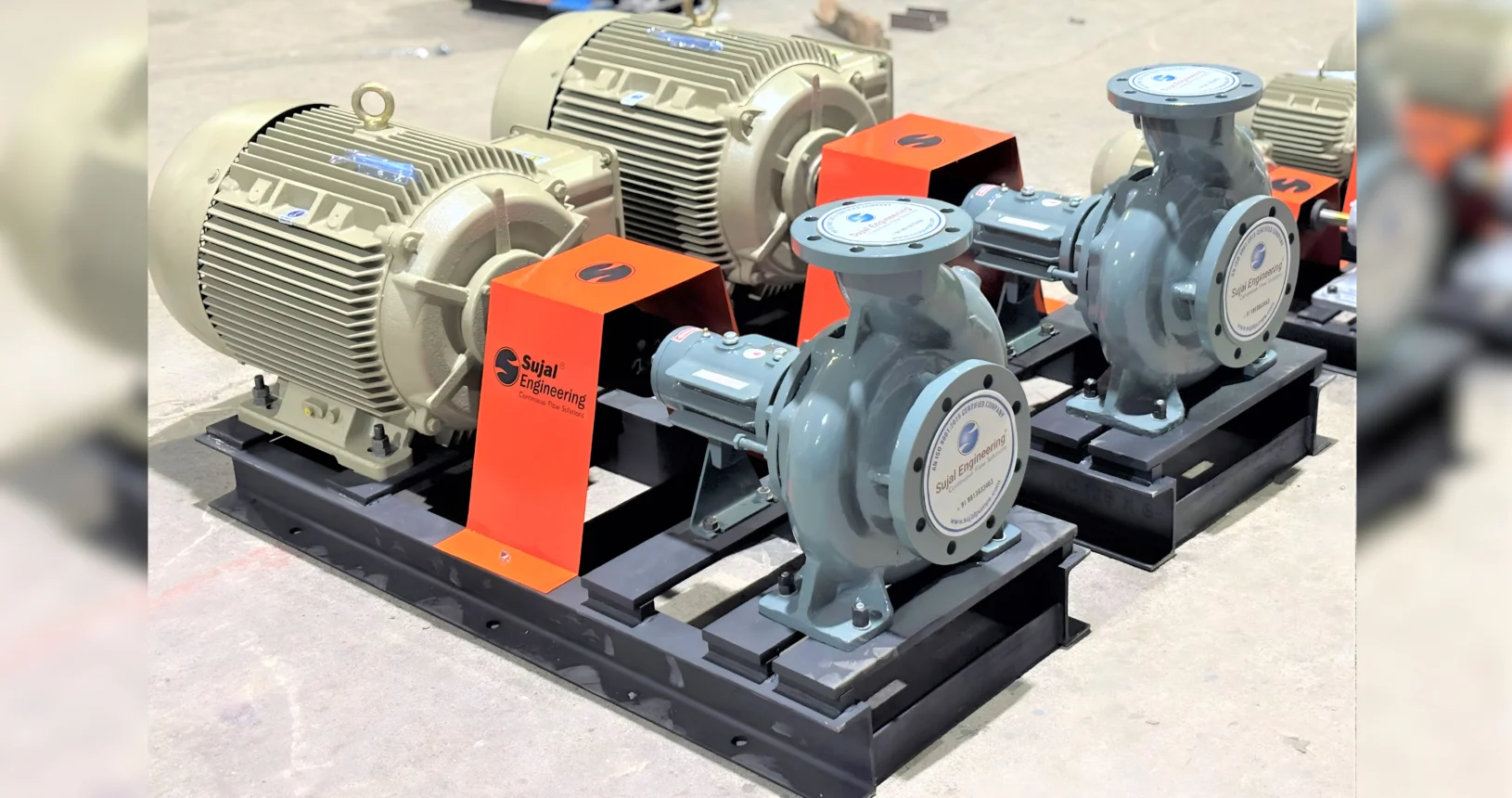

SAPP Series Thermic Fluid

Hot Oil Pump

High-performance pumping for thermal oils up to 400°C.

Sujal Engineering is a leading manufacturer and exporter of thermic fluid hot oil air-cooled pumps trusted by industries worldwide for their high efficiency, durability, and reliability. Our pumps are specially designed for the smooth and safe circulation of mineral and synthetic thermal oils at temperatures up to 400°C, making them ideal for a wide range of industrial heating and thermal fluid applications.

Each thermic fluid hot oil air-cooled pump from Sujal Engineering is engineered with precision to ensure consistent performance under high-temperature conditions. The pumps feature robust construction and optimized hydraulic design, allowing them to deliver long-lasting operation with minimal maintenance. This makes them a preferred choice for industries such as chemical processing, petrochemicals, pharmaceuticals, and other high-temperature industrial systems.

Technical Specification

| Specification | Details |

|---|---|

| Type | Air Cooled, End-Suction, Horizontal, Single Stage – Thermic fluid pump. |

| Capacity | up to 1100 m3/hr |

| Head | up to 150 Meter |

| Max. Allowed Working Pressure | up to 15 kg/cm² |

| Size | 32mm to 200mm |

| Speed | up to 3500 rpm |

| Temperature | up to 400° C |

| Material of Construction (M.O.C.) | Grey Cast Iron, Cast Steel WCB grade, Alloy Cast Steel, S.S 304, S.S 316 etc. |

| Connection Type | Flange |

Download Our Thermic Fluid Hot Oil

Get the complete specifications, features, and performance details of our Thermic Fluid Hot Oil in this downloadable catalog.

Designed for durability and efficiency.

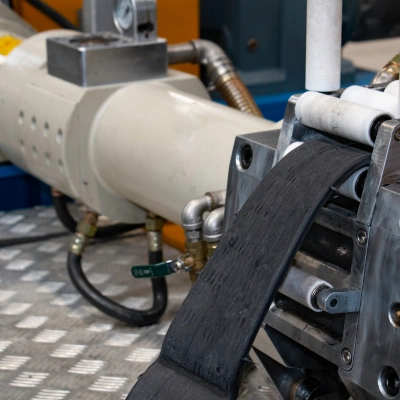

Smart Design Features

- Main dimensions according to DIN 24256 (ISO 2858).

- No need to cool the pump externally. Thanks to mechanical design, the temperature drops from casing to the bearing rapidly with the help of natural convection.

- The shaft is designed according to the minimum heat transfer criteria.

- The mechanical seal stands between two roller bearings and close to the roller bearing on the coupling side. This gives the mechanical seal longer working life since it is on a lower temperature region.

- The bearing housing features fins to enhance natural convection.

- Maximum component interchangeability – identical parts fit multiple pump sizes, simplifying maintenance and reducing spare part inventory.

- Single entry, closed impeller is hydraulically thrust compensated and dynamically balanced

- Maintenance is very much easier, the impeller shaft & other rotating parts being removable with no need to disconnect the suction and delivery pipes.

Precision Flow and Maximum Heat Transfer

Partner with us for reliable pumping solutions.

Applications of Our Thermic Fluid Hot Oil Pumps

Trusted Across Multiple Applications

Thermic Fluid Hot Oil Pump – SAPP Series

Get Your Custom

Pump Solution Today

Talk to our experts to specify the right thermic fluid hot oil pump for your industrial needs —

precise performance, durable build, and prompt delivery.

See the excellence we deliver.

Other Products

Explore Our Product Range