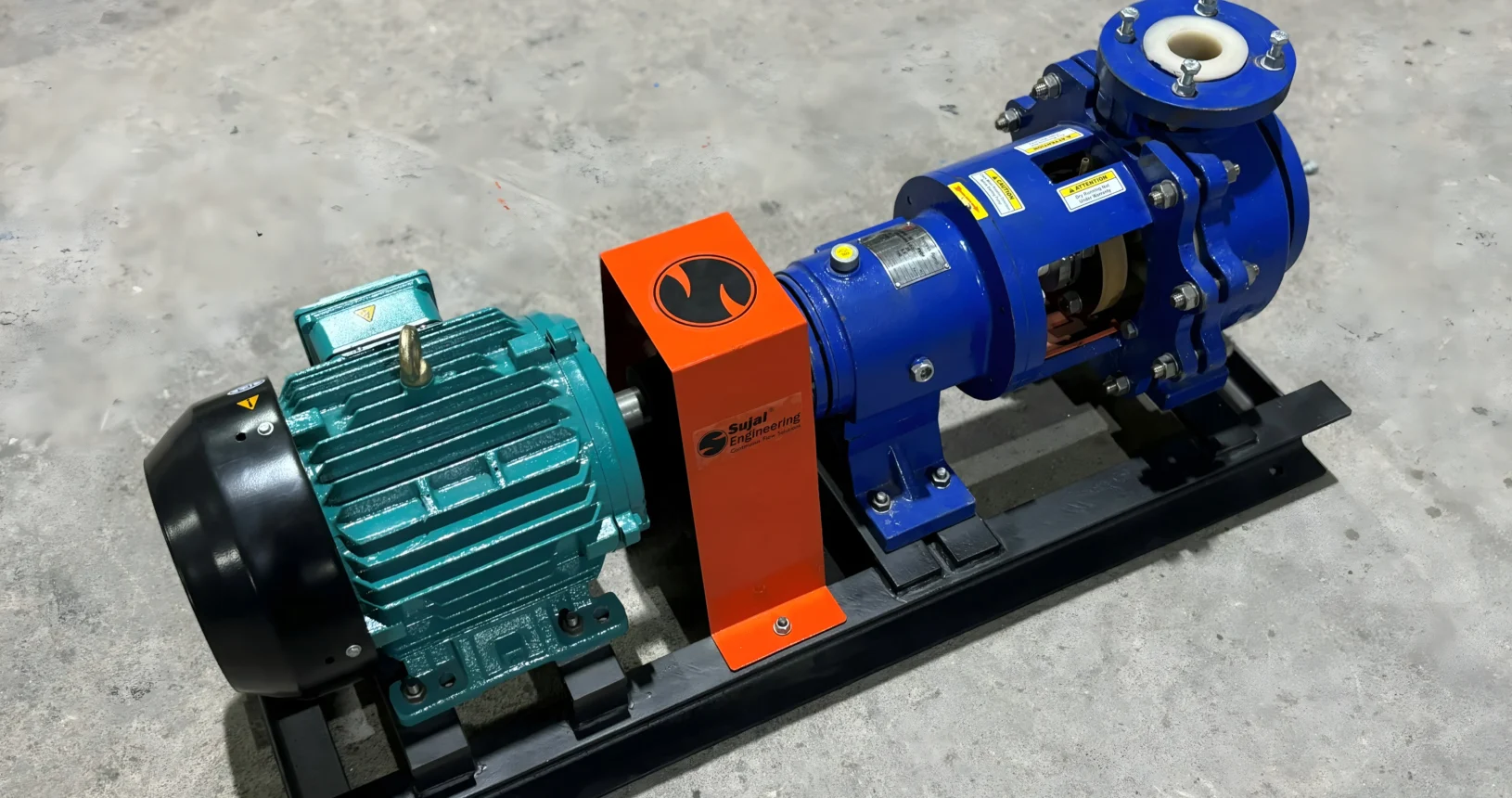

SPVDF Series PVDF Pump

Precision flow with unmatched corrosion protection.

Sujal Engineering is a trusted manufacturer and exporter of PVDF pumps, engineered for handling highly corrosive and hazardous chemicals. Built from high-grade Polyvinylidene Fluoride (PVDF), these pumps ensure exceptional chemical resistance, durability, and reliability. They are ideal for transferring acids, alkalis, and other aggressive media where metallic pumps cannot perform.

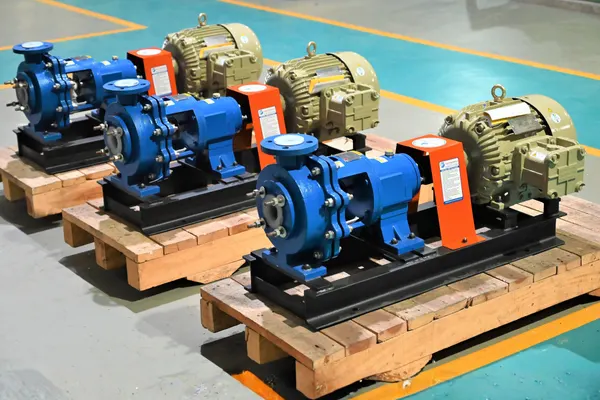

With years of experience in pump manufacturing and global exports, Sujal Engineering provides PVDF pumps that meet international standards for quality and performance. Each unit is thoroughly tested to ensure leak-proof operation and long-term durability in challenging industrial environments. We deliver efficient, corrosion-proof flow solutions trusted by industries across India and overseas.Technical Specification

| Specification | Details |

|---|---|

| Type | Non-Metallic Anti Corrosive PVDF Pump |

| Capacity | up to 280 m3/hr |

| Head | up to 90 Meter |

| Pressure | up to 9 kg/cm2 |

| Size | 25 mm to 100 mm |

| Speed | up to 3500 rpm |

| Temperature | up to 150 C |

| Material of Construction (M.O.C.) | Polyvinylidene Fluoride (PVDF) |

| Connection Type | Flange |

Download Our PVDF Pump Catalog

Get the complete specifications, features, and performance details of our PVDF Pump in this downloadable catalog.

Designed for durability and efficiency.

Smart Design Features

- High-grade Polyvinylidene Fluoride (PVDF) for excellent chemical and corrosion resistance.

- Heavy-duty end suction, back pull-out design for easy maintenance and service.

- Available with mechanical seal (PTFE bellow) or gland packing, depending on service condition.

- High-strength EN-8 / SS 316 shaft with Ceramic sleeve protection for zero contact with liquid.

- Heavy-duty bearings for longer life and vibration-free operation.

- Semi-open and dynamically balanced impeller for efficient hydraulic performance.

- Capable of handling temperatures up to 120°C continuous service, and up to 150°C intermittently, ensuring suitability for hot and corrosive liquids.

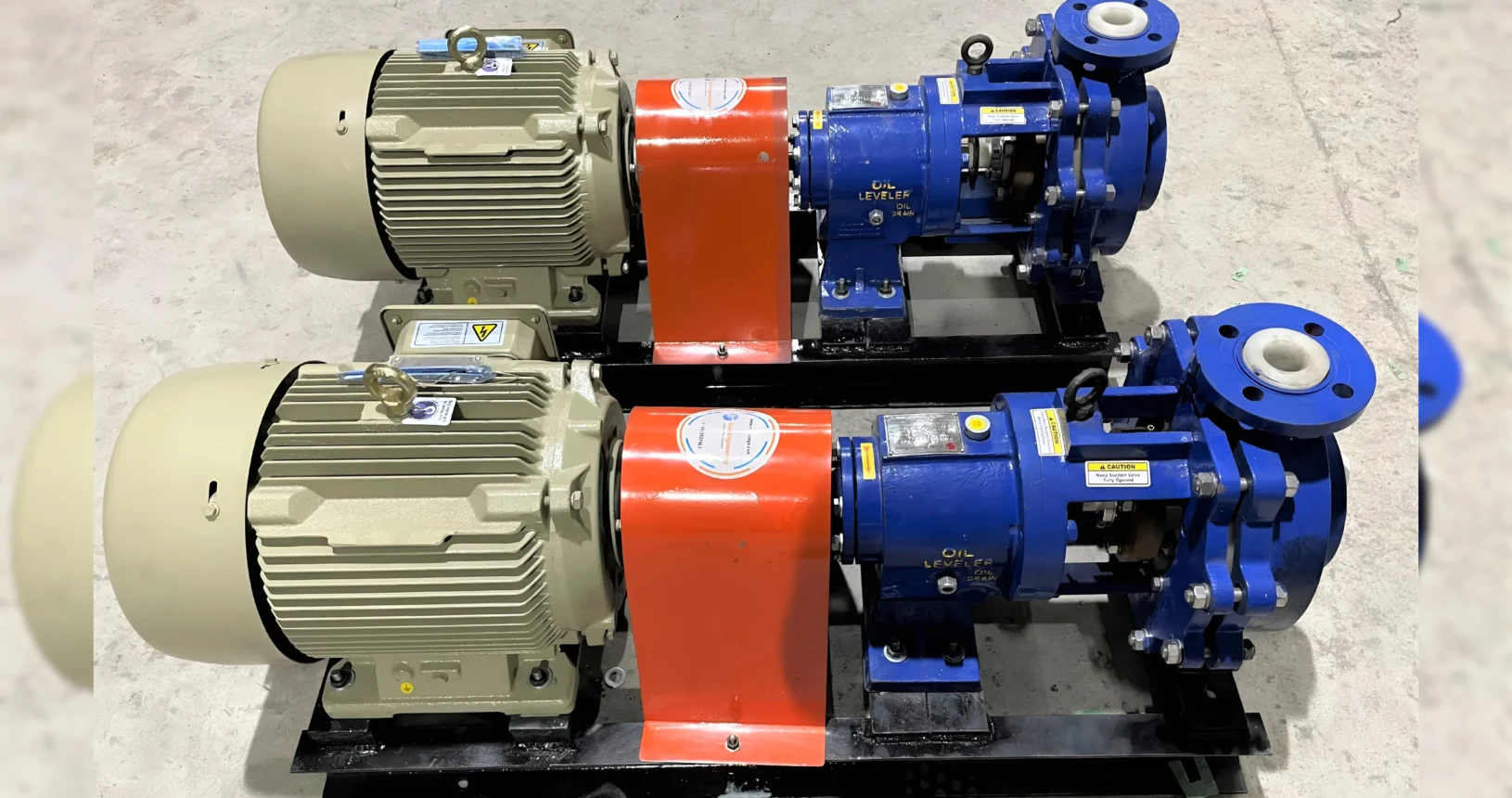

- Mounted on a robust base frame with precise alignment between pump and motor for easy installation, inspection, and maintenance.

Powering performance in corrosive environments.

Partner with us for reliable pumping solutions.

Applications of SPVDF Series PVDF Pump

Trusted Across Multiple Applications

PVDF Pump – SPVDF Series

Get Your Custom

Pump Solution Today

Talk to our experts to specify the right SPVDF Series PVDF Pump for your industrial needs —

precise performance, durable build, and prompt delivery.

See the excellence we deliver.

Other Products

Explore Our Product Range