A thermic fluid pump has been designed to circulate hot oil and high-temperature liquid which makes this pump more suitable for applications in heat transfer plants.

Sujal Engineering is the world’s largest manufacturer of thermal fluid pumps used to move heat-transfer oils at high temperatures. Our thermic Fluid Pump is also referred to as a hot oil circulating pump. It is the finest option for better leakage control and energy savings.

Our thermal fluid pumps are employed in oil refineries, food, chemical, and textile sectors, as well as saltwater desalination facilities, and are suited for both organic and inorganic fluids. These pumps include a self-cooling function, making them suited for use in heat transfer plants and the handling of organic heat transferring of oils. These pumps are built with heavy-duty bearings to meet the most recent industry requirements.

Technical Specification:

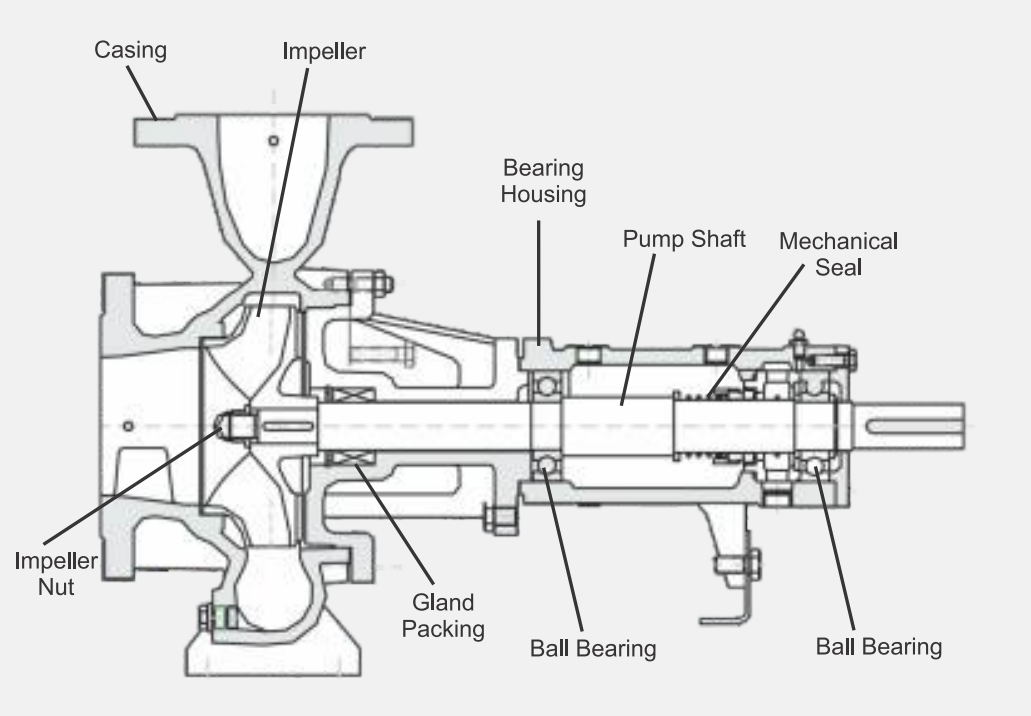

Type: End-Suction, Horizontal, Single Stage, Air Cooled Pump – Thermic fluid pump.

| Operating Range | |

| Size | 25 to 300 mm |

| Operating Pressure | 15 Bar |

| Speed Range | Up to 3500 RPM |

| Capacity Range | up to 360 m3 / h |

| Head Range | up to 150 m |

| Temperature | up to +350 C Max. |

| M.O.C | A216 Carbon Steel (WCB), SS 316, SS 316L, SS 304, Graded Grey Cast Iron |

Thermic Fluid Hot Oil Pump – SAPP Series

Thermic Fluid Hot Oil Pump are used in following applications and industries:

- Thermic Fluid handling

- Hot Oil Transfer

- Edible Oil Industries

- Food & Drug Industry

- Plastic & Synthetic Fiber Industry

- Baking & Heating Application

- Vulcanizing & Heating industry.

- Leather Industries

- Wood & Ply Board Industries

- Rubber Industries

- District Heating System

- Various Chemical Industries

- Chemical & Refinery plants

- Paper & Sugar Industry

- Textile Industry

Material of Construction

- A 216 Carbon Steel (WCB)

- SS 316

- SS-316L

- SS 304

- Graded Grey Cast Iron