How Impeller Balancing Optimizes Pump Performance

Impeller balancing is a critical maintenance procedure that optimizes pump performance by ensuring weight is distributed perfectly evenly across the rotating impeller. This precision process eliminates damaging vibration, which in turn reduces wear on bearings and mechanical seals, lowers energy consumption, and can significantly extend the total lifespan of your pump.

For any industrial operation, an unbalanced impeller is a primary driver of costly downtime and complete pump failure. In high-demand sectors like chemical processing, power generation, or wastewater treatment, believing heavy-duty pumps is a given. Understanding how to protect that investment is key.

At Sujal Engineering, we’ve seen directly how this single maintenance step can be the difference between a reliable, efficient system and a constant source of operational headaches. This guide gives details of what impeller balancing is, why it’s essential, and how it directly impacts your bottom line.

What Is Impeller Balancing, and Why Is It So Important?

To understand the solution, we first have to look at the core component.

What is a pump impeller?

The impeller is the rotating heart of a centrifugal pump. As it spins, its vanes grab the fluid (be it water, chemicals, or slurry) and sling it outwards using centrifugal force. This action creates the pressure and flow that makes the pump work.

Think of it as a pump engine. It operates at incredibly high speeds, often thousands of RPMs (revolutions per minute).

What does ‘impeller balancing’ actually mean?

Impeller balancing is a process that corrects any uneven weight distribution on the impeller. Even tiny manufacturing imperfections or accumulated wear can create a “heavy spot” on one side.

When this heavy spot spins at high speed, it creates a powerful centrifugal force that pulls the entire rotating assembly off its true center. This creates a “wobble,” which we feel as vibration. Balancing involves precisely adding or (more commonly) removing tiny amounts of material to make the impeller’s center of mass align perfectly with its center of rotation.

Why is impeller balancing non-negotiable for pump maintenance?

An unbalanced impeller is not a minor issue; it’s a ticking time bomb. The constant, excessive vibration it generates sends destructive forces throughout the entire pump assembly.

This vibration is the root cause of most premature pump failures, including bearing destruction, mechanical seal leaks, and even shaft wear. Balancing is the single most effective way to eliminate this primary failure mode, making it an essential part of any serious pump reliability program.

What Happens If an Impeller Is Unbalanced?

Ignoring an unbalanced impeller will lead to a range of costly problems. These features are clear warning signs that your pump is under extreme stress.

What are the most common signs of an unbalanced impeller?

If you notice any of the following, an unbalanced impeller is a highly likely culprit:

- Excessive Vibration: This is the number one symptom. The pump casing may feel like it’s shaking or humming loudly.

- Loud, Repetitive Noise: You may hear a rumbling or grinding noise that gets worse as the pump speed increases.

- Frequent Bearing Failure: The unbalanced forces put immense stress on the pump bearings, causing them to overheat, wear out, and fail long before their expected service life.

- Leaking Mechanical Seals: Vibration causes the precision faces of a mechanical seal to crack and separate, allowing the pumped fluid to leak out.

- Increased Energy Consumption: The pump motor has to work much harder to fight against the vibration and imbalance, drawing more power and driving up utility costs.

What are the main causes of pump imbalance?

Imbalance isn’t always a manufacturing defect. It can be introduced at several points in a pump’s life:

- Manufacturing Standards: No manufacturing process is perfect. Small casting variations or machining inconsistencies can create an initial, minor imbalance.

- Uneven Wear: In pumps handling abrasive fluids, like the Self-Priming Mud Pumps used in mining, the impeller wears down unevenly over time.

- Corrosion or Pitting: For Polypropylene (PP) Pumps or stainless-steel units in chemical plants, corrosion can eat away at the impeller non-uniformly.

- Build-up or Clogging: In wastewater applications, solids can get trapped or built on one side of the impeller, creating a temporary but severe imbalance.

- Improper Repairs: A previous repair that involved welding or grinding on the impeller without re-balancing it can easily introduce a new imbalance.

How does imbalance affect overall pump performance?

An unbalanced impeller is an efficiency killer. The energy that should be going into moving fluid is wasted in the form of vibration and heat.

This means your pump won’t achieve its designed flow or pressure (its “best efficiency point,” or BEP). You’ll be paying more for electricity for less performance, all while the pump is actively destroying itself from the inside out.

What’s the Difference Between Static and Dynamic Balancing?

When technicians talk about balancing, they usually refer to one of the two methods. While both have their place, only one is truly acceptable for high-speed industrial pumps.

What is static balancing?

Static balancing, also called single-plane balancing, corrects imbalance on only one plane. You can picture this as placing the impeller on a set of frictionless rollers (or “knife edges”) and letting it roll until the heavy spot settles at the bottom.

This method only accounts for static imbalance and is only suitable for very slow, large-diameter components like a pulley or a flywheel. It does not account for forces created when the component is spinning.

What is dynamic balancing?

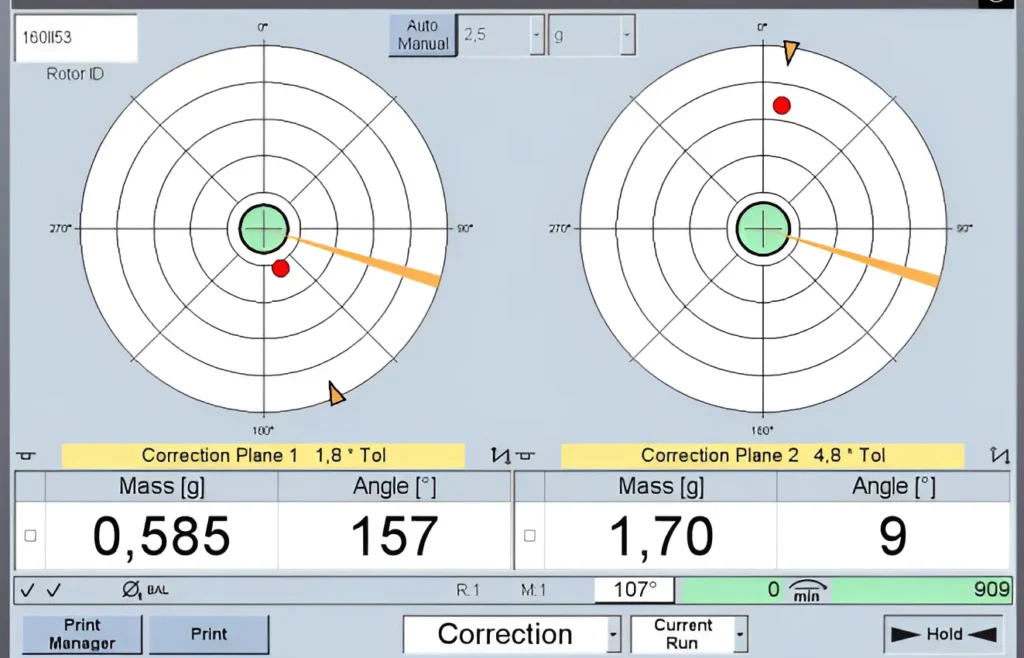

Dynamic balancing, or two-plane balancing, is far more sophisticated. It uses a specialized balancing machine that spins the impeller at high speed and uses electronic sensors to measure the unbalanced forces on two separate planes.

This method detects and corrects both static imbalance (the heavy spot) and “couple” imbalance (where two heavy spots on opposite planes create a twisting force, or “wobble”).

Which method is better for industrial pumps?

Dynamic balancing is the only acceptable method for pump impellers.

Because impellers are relatively thin but spin at high speeds, they are highly susceptible to couple’s imbalance, which static balancing cannot even detect. Any pump maintenance or repair that doesn’t include dynamic balancing is cutting down a critical corner that will almost certainly lead to premature failure.

How Does the Impeller Balancing Process Work?

Dynamic balancing is a precise, data-driven process that requires specialized equipment.

How do technicians identify imbalance?

The process starts with a diagnostic. A technician uses a vibration analyzer on the running pump to confirm that the vibration’s frequency matches the pump’s rotational speed (a “1x RPM” vibration peak). This is the classic signature of imbalance.

How is an impeller balanced?

Once the pump is disassembled, the impeller is mounted in a dynamic balancing machine. Here’s a simplified breakdown of the steps:

- Test Spin: The machine spins the impeller while sensors measure the exact location and amount of the unbalanced forces on two planes.

- Analysis: The machine’s computer calculates precisely how much material needs to be removed (and from where) to correct the imbalance.

- Correction: The technician removes material, usually by grinding or drilling small amounts from the “heavy” side of the impeller. In some cases, small weights may be added to the “light” side.

- Verification: The impeller is rolled again to verify that the imbalance has been corrected and is now within the acceptable limits.

What are the international standards for balancing?

Precision balancing isn’t guesswork. It’s governed by international standards, most commonly ISO 1940-1 (or ANSI S2.19). These standards provide “G-codes” (e.g., G6.3, G2.5, G1.0) that define the acceptable limit of residual imbalance for different types of machinery.

High-performance pumps, especially those in critical service, are typically balanced to a very fine grade, like G2.5 or even G1.0, to ensure maximum reliability.

The Top 5 Benefits of a Well-Balanced Impeller

The positive effects of impeller balancing are immediate and compound over time, saving you significant money and operational stress.

1. Drastic Reduction in Pump Vibration and Noise

This is the most obvious and immediate benefit. A dynamically balanced impeller runs smoothly and quietly. This isn’t just a quality-of-life improvement; it’s the removal of the primary destructive force acting on your pump.

2. Extended Lifespan for Bearings and Mechanical Seals

Bearings and mechanical seals are the two components most often killed by vibration. By eliminating the root cause, a balanced impeller allows bearings to run cooler and last for their full design life. It also allows mechanical seal faces to stay perfectly aligned, preventing leaks.

3. Significant Improvement in Energy Efficiency

A balanced pump wastes less energy fighting itself. All the motor’s power can be dedicated to its real job: moving fluid. This directly translates to lower voltage draw and reduced electricity bills, an especially critical factor for high-uptime units like Thermic Fluid / Hot Oil Circulating Pumps.

4. Enhanced Pump Reliability and Uptime

This is the goal. A balanced pump is a reliable pump. It is far less likely to fail unexpectedly, allowing you to move from a reactive (“fix it when it breaks”) maintenance model to a proactive, planned one. This means more uptime, more production, and less stress for your operations team.

Is your system unreliable? If you’re constantly fighting pump vibrations or failures, don’t wait for a complete breakdown. Consult the Sujal Engineering team today to help diagnose the root cause.

5. Lower Overall Lifetime Maintenance Costs

When you add it all up, the ROI is clear. You’ll spend less on replacement parts (bearings, seals), less on energy, and, most importantly, you’ll lose less money to unscheduled downtime. The small upfront cost of balancing pays itself many times over.

When Should You Balance Your Pump Impeller?

Balancing isn’t just a one-time fix. It should be a key part of your pump’s entire life cycle.

Is balancing only for new pumps?

No. While quality manufacturers like Sujal Engineering balance all impellers before they leave the factory, balancing should be done any time a pump is serviced.

Should balancing be part of every pump repair?

Yes, absolutely. If your pump is being disassembled for any reason (like a bearing change), the impeller should be dynamically balanced as a standard part of the reassembly procedure. It’s the only way to guarantee reliable, long-lasting repair.

How often should you check for imbalance?

You should regularly monitor your pumps for changes in vibration and noise using predictive maintenance (PdM) techniques. A sudden increase in vibration is a clear signal that an imbalance has developed (perhaps due to wear or build-up) and that the pump needs to be scheduled for service.

How Sujal Engineering Prioritizes Performance

For industries from chemical processing to food and beverage, pump reliability is non-negotiable.

Precision Engineering for Demanding Applications

At Sujal Engineering, we design our pumps – from our tough Centrifugal Process Pumps to our high-viscosity Rotary Gear Pumps – with reliability at their core. This commitment starts with precision-balanced components designed to operate smoothly even in the harshest conditions. We understand that a pump’s true cost is its total cost of ownership, and that starts with a reliable build.

Beyond Balancing: A Holistic Approach to Pump Reliability

Proper impeller balancing is a cornerstone of a reliable system, but it’s part of the bigger picture. Proper installation, correct pump selection for the application, and a strong preventative maintenance program all work together.

Don’t let vibration and imbalance dictate your maintenance schedule. Take control of your pump performance.

Ready to improve your system’s reliability? Explore our full range of industrial pumps designed for efficiency and longevity.

Facing a specific challenge? Contact Us Today and let our engineers recommend the perfect pump for your application.

Frequently Asked Questions (FAQ)

1. What is the main cause of impeller imbalance?

While new pumps can have minor manufacturing imbalances, the most common cause in working pumps is uneven wear from abrasive liquids or corrosion. Build-up of solids (clogging) in wastewater applications is also a frequent culprit.

2. Can you overbalance an impeller?

No, not in the sense of making it “too balanced.” The goal is to get the residual imbalance as close to zero as possible. However, a technician can balance an impeller incorrectly by removing material from the wrong spot or using the wrong tolerance, which is why it’s vital to use an experienced professional and proper dynamic balancing equipment.

3. How much does impeller balance cost?

The cost of balancing an impeller is minimal compared to the cost of a new pump or the production losses from downtime. It’s almost always a high-ROI investment. The cost will vary based on the impeller size and the technician’s time, but it is far less expensive than replacing bearings and seals prematurely.

4. Does impeller balancing improve pump efficiency?

Yes, absolutely. An unbalanced impeller wastes motor energy by converting it into vibration and heat. A balanced impeller runs more efficiently, allowing more of the motor’s power to be used for pumping fluid, which can lead to measurable reductions in energy consumption.

5. What is the difference between balancing and alignment?

This is a common point of confusion.

- Balancing corrects for uneven weight distribution on a rotating component (like the impeller).

- Alignment refers to the perfect, co-linear alignment between two separate components, such as the pump shaft and the motor shaft.