Polypropylene Pump Manufacturers in India for Global Industries

Introduction to Polypropylene (PP) Pumps in the Global Market

Handling corrosive fluids is one of the toughest jobs in any industry. It is a constant battle against wear and tears. If you manage a chemical plant, a steel mill, or a water treatment facility, you know the pain of pump failure.

It usually happens at the worst time. A seal breaks. The casing cracks. Suddenly, dangerous acid is leaking onto your floor. Your production line stops. Your team has to scramble to fix it. This downtime costs your money every single minute.

The culprit is often the pump material. Standard metal pumps simply cannot handle aggressive chemicals for long. They rust. They corrode. They failed.

This is where Polypropylene (PP) pumps change the game.

Polypropylene is a tough, plastic material. It is engineered to fight corrosion. It handles acids and alkalis that would be eaten through stainless steel in weeks.

For years, industries looked to Europe or the USA for these high-quality pumps. But times have changed.

Sujal Pumps has emerged as a leading manufacturer in India. We are delivering these high-performance solutions to the global market. We combine precision engineering with a price point that makes sense for your budget. We ensure your plant operates smoothly, without dangerous leaks or expensive pauses.

Key Takeaways:

- Cost-Effective: Indian PP pumps offer massive savings compared to Western brands. You get the same quality for less money.

- Chemical Resistance: These pumps are perfect for Hydrochloric Acid, Sulphuric Acid, and Caustic Soda.

- Global Standards: Sujal Pumps exports ISO-certified products to the USA, the Middle East, and Europe.

- Versatile Application: They are the top choice for pharmaceuticals, electroplating, and chemical processing plants.

Why Global Industries Choose Indian Manufacturers for Polypropylene Pumps

The global market is shifting. Smart business owners are looking for value. They want quality, but they do not want to overpay. This is why more industries are turning to India for their pumping needs.

1. Cost-Effectiveness Without Compromising Quality

Let’s talk about money. Running an industrial plant is expensive. You have energy costs, labor costs, and raw material costs. You do not want to blow your budget on equipment if you don’t have to.

European and American pump brands are excellent. But they come with a very high price tag. You are often paying for the brand name as much as the product.

Indian manufacturers like Sujal Pumps have cracked the code. We have optimized our production costs. We have access to skilled labor and high-quality raw materials at better rates.

What does this mean to you?

It means you can buy a top-tier Polypropylene pump from us at a fraction of the cost of a Western competitor. You do not sacrifice performance. You do not sacrifice durability. You simply keep more profit in your company.

2. Advanced Manufacturing Technology in India

Some people still think Indian manufacturing is about basic tools. That is an old myth.

Today, Indian engineering facilities are world-class. At Sujal Pumps, we use state-of-the-art technology. We use advanced injection molding machines. These machines mold the plastic casings with incredible precision.

We use Computer Numerical Control (CNC) machining. This ensures every shaft and impeller is cut to the exact micro-millimeter. There is no guesswork.

This technological leap ensures consistency. When you order ten pumps, all ten will be exactly the same. They will match strict global tolerances. They will fit perfectly into your existing systems.

3. Strategic Export Capabilities to USA, Middle East, and Europe

You might worry about distance. Is it risky to buy from India if you are in Texas or Dubai?

Not anymore. Sujal Pumps is not just a local player. We are a global exporter. We have built a strong logistics network.

We know how to ship heavy machinery. We know how to package it so it arrives safely. We work with the best freight forwarders.

We regularly ship to major industrial hubs. We send pumps to the oil fields in the Middle East. We send them to chemical plants in Germany. We send them to factories in the USA.

Distance is no longer a barrier. You can get world-class technology delivered to your doorstep, no matter where you are.

Are you looking for a reliable pump partner for your facility?

Request a Quick Quote today. Let us show you how much you can save.

What Makes Polypropylene Pumps Ideal for Corrosive Applications?

You might be asking, “Why is Polypropylene? Why not just use steel?”

The answer lies in chemistry.

1. Superior Chemical Resistance Against Acids and Alkalis

Metals react. It is nature. When you put metal in contact with acid, a chemical reaction starts. Iron turns rust. The metal gets eaten away.

Even expensive “stainless” steel has limits. Strong acids like Hydrochloric Acid (HCL) will attack it. Over time, the metal thins out. It develops pinholes. Eventually, it bursts.

Polypropylene is different. It is a thermoplastic polymer. In simple terms, it is chemically “inert.” It does not react.

You can fill a Polypropylene pump with HCL. You can fill it with dilute sulfuric acid. You can fill it with caustic soda. The pump does not care. It stays strong. It does not dissolve. It does not rust.

This makes it the safest choice for transferring dangerous fluids. It protects your workers and your environment.

2. High Thermal Stability and Durability

Chemical processes often involve heat. Fluids rarely have room temperatures. They are often hot.

Some plastics get soft when they get warm. They warp. They lose their shape. If a pump casing warps, the insides rub together. The pump fails.

Our Polypropylene pumps are built for heat. They maintain their structural integrity up to 70°C (158°F). They stay rigid. They keep their shape.

This thermal stability is crucial. It ensures the pump keeps running smoothly, even when the fluid gets hot. It means you don’t have to stop production to let the pump cool down.

3. Leak-Proof and Run-Dry Capabilities

The biggest nightmare for a plant manager is a leak.

A chemical leak is a safety hazard. It can burn workers. It can damage the floor. It can result in huge fines from environmental agencies.

Safety is non-negotiable for us. Our pumps feature advanced mechanical seals. These seals are designed to keep the liquid inside the casing, where it belongs.

We also know that mistakes happen. Sometimes, a tank runs empty. The pump keeps running with no liquid. This is called “running dry.”

For a normal pump, this is fatal. The friction builds up heat instantly. The parts melt. The pump is destroyed in minutes.

Our pumps are smarter. Specific models are designed to withstand temporary run-dry situations. They are tough enough to survive operator errors. This protects your motor. It protects your investment.

Sujal Pumps: Leading Polypropylene Pump Manufacturer in India

Who are we? Why should you trust us?

1. Overview of Sujal Engineering’s Expertise (20+ Years Experience)

We are not new to this. Sujal Pumps has been in the game for over two decades.

We started small. We listened to our customers. We learned what makes a pump fail. We learned what makes a pump last.

Over the last 20 years, we have evolved. We have grown from a local supplier into a global exporter. We have solved thousands of fluid handling problems.

We understand fluid dynamics. We understand friction loss. We understand chemical compatibility. When you talk to us, you are talking to experts who have seen it all.

2. Customization Capabilities for Niche Industrial Needs

Every factory is different. Your piping layout is unique. Your chemical mixture is unique.

One size rarely fits all.

Big “off-the-shelf” brands often say, “Take it or leave it.” We don’t do that.

Do you have a unique flow rate requirement? We can adjust the impeller. Do you need a specific flange standard to match your German pipes? We can do that. Do you need a mobile trolley to move the pump around? We can build it.

We customize our pumps to fit your reality. This ensures a hassle-free installation. You won’t have to rebuild your whole piping system just to fit our pump.

3. Commitment to International Quality Standards (ISO Certified)

Quality is not just a buzzword for us. It is a promise.

We are an ISO-certified company. This means we follow strict international rules for manufacturing.

Every single pump that leaves our factory goes through a test. We pressure test the casing to ensure it won’t burst. We test the seals to ensure they don’t leak. We run the motor to check the performance.

You never get a “lemon.” You receive a product that is certified to perform. You get paperwork that proves it. You get peace of mind.

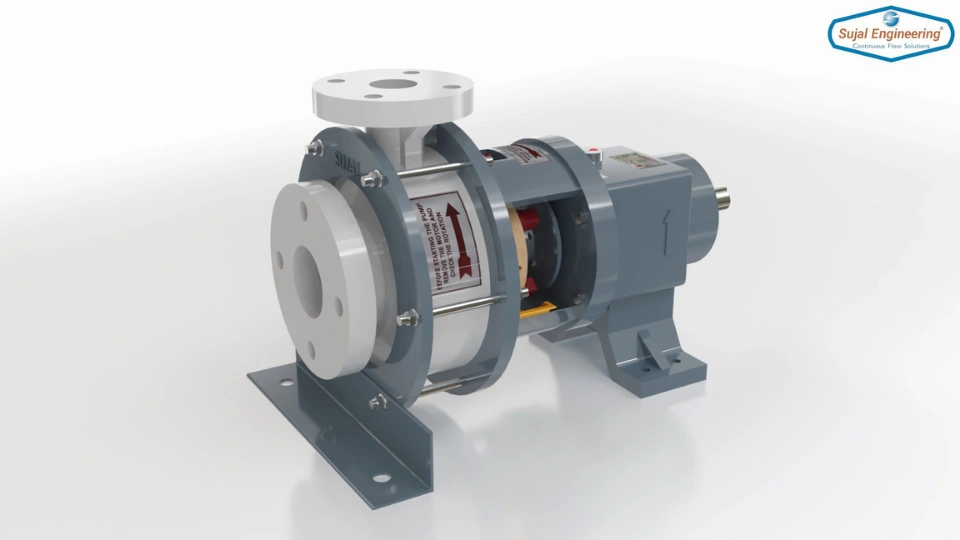

Spotlight on SPP and SPPL Series: Technical Excellence

Let’s look under the hood. Our SPP and SPPL series are our flagship products. Here is why they are special.

1. Design Features: Horizontal Radially Split Volute Casing

That sounds complicated, but it is actually simple.

“Radially split” means the casing opens up easily. Imagine you need to inspect the inside of the pump. With some old designs, you have to disconnect all the pipes. It is a huge job.

With our design, you can access the internal parts without disturbing the main piping. You can check the impeller. You can clean the casing.

This makes maintenance fast. It reduces your downtime. Your maintenance team will love this feature.

2. Material Construction: PP, GRP, PVDF, and UHMWPE

We don’t just stop at standard Polypropylene. We offer a menu of materials to suit your exact needs.

- PP (Polypropylene): Great for general acids and alkalis.

- GRP (Glass Reinforced Polypropylene): This has glass fibers mixed in. It is stronger and stiffer. It handles higher pressure.

- PVDF (Polyvinylidene Fluoride): This is the heavy hitter. It handles higher temperatures and even more aggressive chemicals.

- UHMWPE: This stands for Ultra-High Molecular Weight Polyethylene. It is incredibly tough. It resists abrasion. If your fluid has sandy particles or sludge, this is the material you need.

3. Performance Metrics: Capacity, Head, and Speed

Our pumps are beasts. They are built to work hard.

- Capacity: We can move up to 300 cubic meters per hour. That is a massive volume of liquid.

- Head: We can push liquid up to 60 meters vertically. That is as high as a 20-story building.

- Speed: Our motors run between 1450 and 2900 RPM. This gives you flexibility in pressure and flow.

We engineer our pumps to deliver high flow and high pressure. They meet the demanding throughput of modern industrial plants.

Key Global Industries Utilizing Indian Polypropylene Pumps

Where are these pumps used? Almost everywhere.

1. Chemical and Petrochemical Processing

This is the most obvious one. Chemical plants move dangerous liquids all day long.

They transfer raw solvents from tanker trucks to storage tanks. They pump acids into mixing reactors. They move the final product to filling lines.

Our pumps are the heartbeat of these plants. They handle volatile organic compounds. They handle corrosive acids. They do it safely and reliably.

2. Pharmaceutical and Active Pharmaceutical Ingredients (API)

Making medicine requires extreme purity. You cannot have rust in your medicine.

Stainless steel can sometimes leach tiny amounts of iron or chromium into the product. This is a disaster for pharma companies.

Our PP pumps are inert. They do not learn anything. They ensure your API products stay 100% pure. They help you comply with strict health safety standards.

3. Effluent Treatment Plants (ETP) and Water Treatment

Cleaning water is a dirty job.

Factories produce wastewater full of toxins. To clean it, you have to treat it. You have to add lime to balance the pH. You have to add acids to neutralize waste. You have to add coagulants to clump dirt together.

All these chemicals are corrosive. Sujal Pumps are widely used in ETPs. They dose these chemicals accurately. They withstand the harsh environment of a wastewater plant.

4. Steel Rolling Mills and Electroplating Industries

Steel mills are tough places. They have “pickling lines.”

In a pickling line, steel sheets are dipped into a bath of hot acid. This acid eats away rust and scale to clean the steel.

Our pumps circulate this hot acid. They stand up to constant exposure. They keep the acid moving, so the steel gets cleaned evenly. Without these pumps, the production line will stop.

5. Paper, Pulp, and Fertilizer Plants

Making paper involves a lot of chemicals. It involves bleaching agents to make the paper white.

Making fertilizers involves phosphoric acid and ammonia. These are nasty fluids. They are often thick slurries.

Our robust pump design handles this dual challenge. It fights chemical corrosion. It also fights the abrasion from the thick slurry. It is a tough pump for a tough job.

Not sure which pump fits your industry?

Consult with Our Experts for a free application analysis.

Comparing Metal Pumps vs. Polypropylene Pumps for Corrosive Fluids

Many people ask us to compare the two. “Why should I switch from metal to plastic?”

Here is a clear breakdown of the differences.

| Feature | Metal Pumps (Stainless Steel/Alloys) | Polypropylene (PP) Pumps |

| Initial Cost | High. Exotic alloys like Hastelloy are very expensive. | Low. PP is much more affordable to manufacture. |

| Corrosion Resistance | Limited. Even high-grade steel eventually corrodes with strong acids. | Excellent. PP is chemically inert and does not rust. |

| Weight | Heavy. Requires cranes or heavy equipment to move and install. | Lightweight. Easy to handle, transport, and install manually. |

| Maintenance Cost | High. Parts are expensive. Corrosion leads to frequent repairs. | Low. Simple design and no corrosion mean fewer repairs. |

| Energy Efficiency | Variable. Heavy rotating parts can consume more power. | High. Smooth internal surfaces reduce friction, saving energy. |

| Lifespan in Acid | Short to Medium. Constant chemical attack wears them down. | Long. Can last for years even in harsh acid environments. |

| Painting Required | Yes. The exterior needs painting to prevent atmospheric rust. | No. The material is colored through and never needs paint. |

1. Cost Analysis: Initial Investment vs. Maintenance

Look at the table. Metal pumps are lost on cost.

If you buy a super-alloy pump, you pay a fortune upfront. Then, you pay for expensive spare parts.

PP pumps save you money on day one. They also save you money every year on maintenance. The Return on Investment (ROI) is much better.

2. Corrosion Resistance and Longevity Factors

It is simple physics. Metal wants to oxidize. Plastic does not exist.

A Polypropylene pump will simply outlast a metal equivalent in an acid application. It is the smarter choice for longevity.

3. Weight and Installation Advantages

Think about your maintenance team.

Dragging a heavy metal pump out of a pit is hard work. It is dangerous. You need chains and pulleys.

A PP pump is much lighter. Two people can often lift it. It is easier to align. It puts less stress on your piping. It makes the job easier and safer for your staff.

How to Select the Right Polypropylene Pump for Your Industry

Choosing a pump can feel overwhelming. There are so many numbers and charts. Let’s simplify it.

1. Analyzing Fluid Properties: Temperature, Viscosity, and Acidity

Always start with the liquid. What exactly are you pumping?

- Temperature: Is it hot? If it is over 70°C, we need to upgrade you to PVDF.

- Viscosity: Is it thick like honey? Or thin like water? Thick fluids need a slower motor speed.

- Acidity: What is the concentration? 10% acid is different from 98% acid.

Knowing these details ensures we pick the right material. It prevents premature failure.

2. Determining Flow Rate and Head Requirements

This is about the work the pump needs to do.

- Flow Rate: How fast do you need to move the liquid? Do you need to fill a tank in 10 minutes or 1 hour?

- Head: This is tricky. It is not just the height. It is friction in the pipes too.

We help you calculate the “Total Dynamic Head.” Undersizing a pump leads to poor performance. Oversizing it wastes electricity. We find the “sweet spot” for maximum efficiency.

3. Evaluating Mechanical Seal vs. Gland Packing Options

How do you want to seal the shaft?

- Mechanical Seal: This uses two flat faces pressing together. It is very tight. It is best for expensive or toxic chemicals. It costs a bit more, but it is cleaner.

- Gland Packing: This uses braided rope squeezed around the shaft. It is meant to drip a little bit to keep cool. It is cheaper. It is okay for water or non-hazardous waste.

For most chemical applications, we recommend a Mechanical Seal. It is safer.

Challenges in Sourcing Industrial Pumps Globally and How Sujal Pumps Solves Them

Buying from another country can make me feel scared. What if things go wrong? We have solved these problems.

1. Overcoming Logistics and Shipping Barriers

Shipping heavy equipment is an art.

We handle all the paperwork. We handle customs forms. We handle insurance. We use specialized wooden crates that protect the pump from shock and moisture during the sea voyage.

We ensure your pump arrives at your nearest port or even your factory door without a scratch. You don’t have to stress about logistics. We will do it for you.

2. Ensuring Post-Sales Support and Spare Parts Availability

A pump is a machine. Eventually, the parts wear out.

You might worry, “If I buy from India, how do I get a spare part?”

We thought of that. We maintain a huge stock of essential spares. We have shelves full of impellers, seals, and shafts.

When you need a part, we dispatch it immediately via air freight. It can reach you in a few days. We support you long after the sale is done.

3. Meeting Diverse International Compliance Standards

The USA has different rules than Europe. Europe has different rules than Saudi Arabia.

Our manufacturing process is flexible. We align with global standards.

If you need a specific type of motor efficiency (like IE3 or IE4), we can supply it. If you need specific safety certifications, we provide them. We ensure our pumps meet the compliance laws of your specific region.

Conclusion: Partner with India’s Best for Global Fluid Handling Success

The industrial world is competitive. To win, you need equipment that works hard and costs less.

Selecting the right Polypropylene pump is crucial. It is the heart of your fluid operations. If the pump stops, the factory stops.

Sujal Pumps offers you a unique opportunity. You get world-class engineering. You get extreme durability. You get expert support. And you get it all at a price that boosts your bottom line.

Whether you are in the USA, Europe, or the Middle East, our pumps are ready. They are ready to handle your toughest acids. They are ready to improve your efficiency.

Don’t let corrosion eat into your profits. Don’t let expensive downtime slow you down. Make the smart switch to Indian manufacturing excellence.

Contact Sujal Pumps today. Let’s discuss your requirements. Let’s build a custom solution that solves your problems once and for all.

Need help selecting the perfect pumps for your biogas plant?

Sujal Engineering’s technical experts are ready to analyze your requirements and recommend solutions driven by decades of industrial pumping experience.

Frequently Asked Questions (FAQs) About Polypropylene Pumps

1. What chemicals can I safely transfer using a Sujal Pumps Polypropylene pump?

Our pumps are beasts when it comes to chemicals. They are excellent for handling aggressive acids like Hydrochloric Acid (HCL), Sulphuric Acid, Phosphoric Acid, and alkalis like Caustic Soda. They handle these without any risk of corrosion or rust.

2. Are Indian-made PP pumps really as durable as the expensive imported brands?

Yes, absolutely. Sujal Pumps manufactures to strict international ISO standards. We use the same high-grade raw materials. You get the same high durability and reliable performance as European brands, but at a much better price point.

3. How hot can the fluid be when using a Polypropylene pump?

Standard Polypropylene pumps work best for fluids up to 70°C (158°F). If your process runs hotter than that, don’t worry. We can upgrade you to our PVDF material pumps, which can handle heat up to 120°C safely.

4. Do you ship pumps to countries like the USA, UAE, or Saudi Arabia?

Yes, we export globally. We have a dedicated logistics team. They manage safe shipping, crating, and all customs documentation to deliver pumps right to your facility, anywhere in the world.

5. Can I get a custom pump designed for my specific factory setup?

You certainly can. We specialize in custom solutions. We know every factory is unique. Just tell us your flow rate, head pressure, and connection type. We will build a pump that fits your existing system perfectly.

6. What happens if the pump runs dry accidentally?

Running dry is bad for most pumps. However, we offer specific models designed to withstand temporary run-dry conditions. This feature protects your investment from accidental operator errors or tank emptying issues.

7. How quickly can I get spare parts if something breaks down?

We know downtime is expensive. We keep a large stock of essential spares like seals, O-rings, and impellers ready to go. We can dispatch them immediately via air cargo to ensure your plant is back up and running fast.

8. Is a Polypropylene pump better than a Stainless Steel pump for acids?

For most acids, yes. Stainless steel can still corrode over time, especially with strong acids like HCL. Polypropylene is chemically inert. It will never rust. It lasts much longer in acidic environments and costs less.

9. How do I choose the right seal for my chemical pump?

It depends on your fluid. For toxic, expensive, or dangerous chemicals, we recommend a mechanical seal to prevent leaks. For simple wastewater, a gland packing seal might be enough. We can analyze your application and help you decide.

10. How can I get a price quote for my project?

It’s very easy. Just click the “Request a Quote” button on our website. Or, you can email us your requirements directly. Our sales team will analyze your needs and get back to you with a competitive offer very quickly.