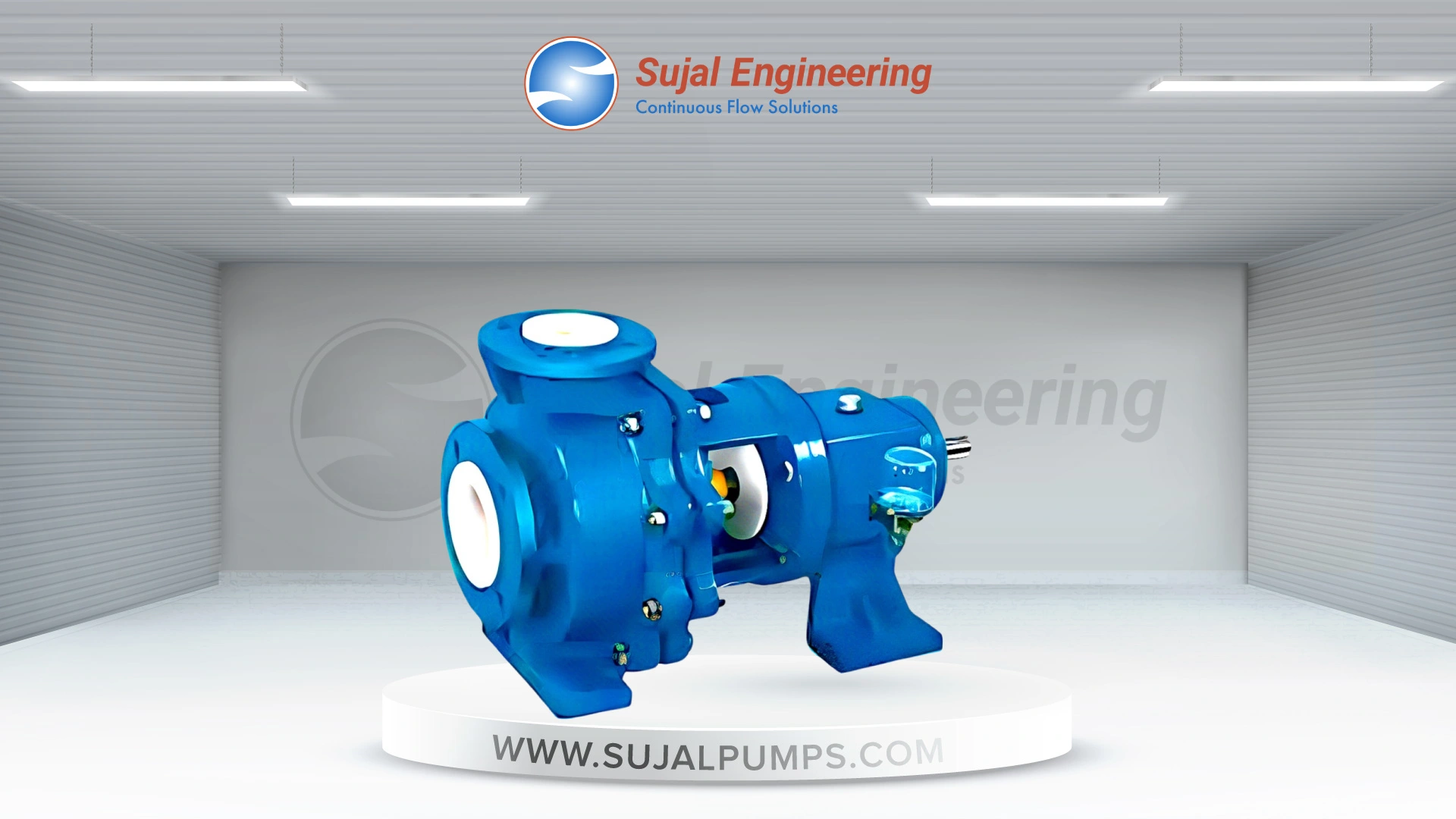

Engineered to transfer aggressive, highly concentrated, and hazardous liquids, PVDF Pump has its use in multiple applications. Appreciated for their durability and chemical and corrosion-resistant properties, these are necessary for various industries and applications.

SUJAL ENGINEERING – one of the well-reckoned PVDF Pump Manufacturers In Ahmedabad, Gujarat. Understand its significance in simplifying and speeding up the process of handling corrosive chemicals.

Salient Features:

- Ensures easy processing by extrusion, injection, compression, rotational moulding, blow moulding etc.

- Chemical inactive to most alcohols, aliphatic, aromatic organic solvents and acids.

- Known for its mechanical properties and has tensile yard strength up to 55 MPa at 23°C and 10 MPa at 150°C.

- Can be used at a temperature as high as 150°C for the homopolymer grades (without mechanical stress)

- Unaffected by UV (>232nm) and good resistance to gamma radiation.

- Excellent intrinsic fire resistance and can be welded.

Technical Specification:

| Capacity | Up to 280 m³/hr |

| Head | Up to 90 Mtr. |

| Discharge Size | 25 mm to 100 mm. |

| Temperature | Max. 120°C |

| Speed | Up to 3500 rpm |

| Pressure | Up to 9 kg/cm2 C |

| M.O.C. | PVDF |

PVDF Pumps are used in following applications and industries:

- Plastic Industries

- Water Treatment

- Insecticide & Pesticide Plants

- Chemical Plants

- Gas Scrubbing

- Pharmaceutical Industries