How to Maintain Prime in Centrifugal Pumps with a Priming Chamber?

Maintaining prime in centrifugal pumps with priming chambers is very important for optimal pump performance and avoiding costly downtime. The key is understanding proper priming procedures, regular maintenance schedules, and implementing protective measures that keep your industrial pumps running efficiently across chemical, textile, marine, and other industrial applications.

At Sujal Engineering, we’ve helped hundreds of plant managers and maintenance engineers optimize their centrifugal process pumps and chemical pumps for maximum reliability. This detailed guide will walk you through everything you need to know about maintaining prime in your pumping systems.

What is Prime in Centrifugal Pumps?

Prime means your pump is completely full of liquid with no air bubbles inside. Think of it like filling a bottle with water – if there’s air inside, the water can’t flow properly.

When your centrifugal process pumps have prime, they can:

- Move liquid efficiently

- Create proper suction pressure

- Run without overheating

- Use normal amounts of electricity

Without prime, pumps stop working. The spinning impeller just turns air instead of moving liquid. This is called “losing prime” and it’s one of the biggest problems in pump operations.

Why Prime is Critical:

- Prevents pump damage from dry running

- Maintains consistent flow rates

- Reduces energy costs

- Avoids production delays

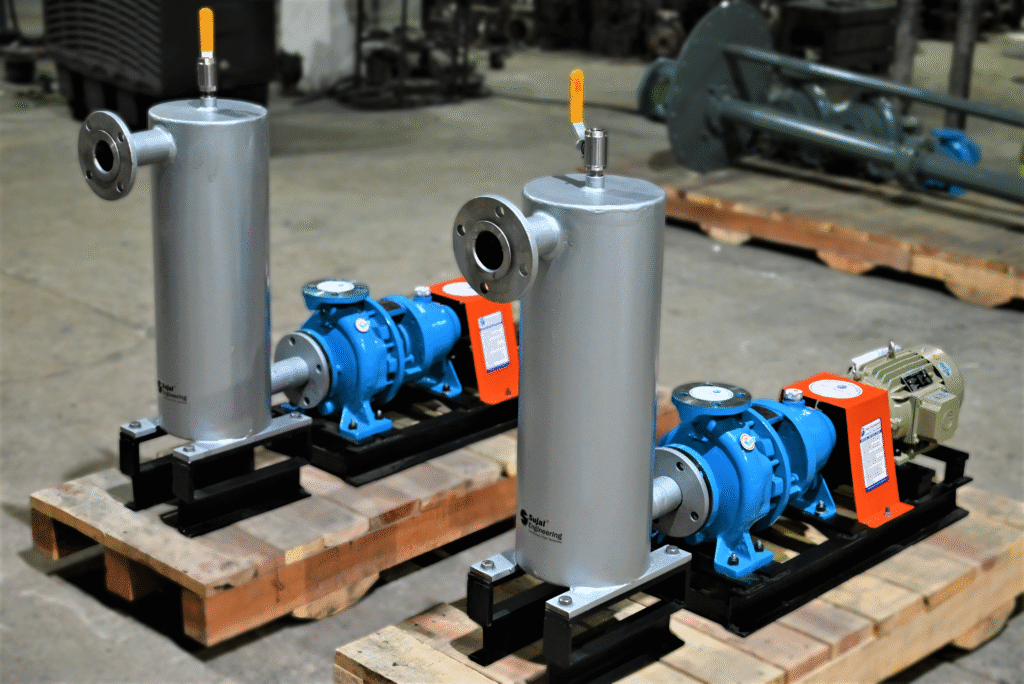

How Does a Priming Chamber Keep Your Pump Primed?

A priming chamber is like a liquid reserve tank that automatically helps your pump stay full of liquid. Here’s how it works:

The Setup: The priming chamber connects directly to your pump’s suction line. It holds extra liquid that can flow into the pump whenever air tries to get in.

Automatic Prime Maintenance: When small amounts of air enter your pump, the priming chamber immediately sends liquid to push that air out. This happens automatically without stopping your pump.

Key Components:

- Liquid storage chamber (sized for your pump)

- Connection to pump suction

- Air vent valves for removing trapped air

- Liquid level indicators

- Fill and drain connections

This system works especially well with chemical pumps and filter press pumps that face changing operating conditions.

What Causes Pumps to Lose Prime?

Understanding why prime is lost helps you stop it before problems arise. The main causes fall into four categories:

Air Leaks (Most Common):

- Loose pipe connections

- Worn mechanical seals

- Cracked suction piping

- Faulty gaskets

Even small air leaks can gradually destroy prime over time, making regular inspection important for reliable operation.

Suction Problems:

- Source tank levels too low

- Blocked strainers or filters

- Suction piping too small

- Excessive suction lift

Vapor Formation: This creates challenges especially with Hot oil pump handling hot liquids. When liquids get too hot, suction pressure drops too low, cavitation occurs inside the pump, or process fluids change to gas, the resulting vapor displaces liquid and destroys prime.

System Issues: Problems like improper venting, wrong pump positioning, poor piping design, or a small priming chamber size can make prime maintenance nearly impossible even with good equipment.

How to Properly Prime Your Centrifugal Pump with a Priming Chamber?

Step 1: Initial Setup and Filling

Before starting your pump, complete these preparation steps:

Pre-Start Checklist:

- Make sure source tank has enough liquid

- Close discharge valve (keep suction valve open)

- Fill priming chamber completely with process liquid

- Open all air vent valves

Filling Process:

- Pour liquid directly into priming chamber until full

- Let liquid flow into pump casing through suction line

- Continue filling until liquid comes out of air vents

- Close air vents when steady liquid flow appears

- Top off priming chamber to maximum level

Complete your setup by verifying no air bubbles appear in the sight glass, checking that all connections are tight, confirming the discharge valve is still closed, and proving the priming chamber is at proper level.

Step 2: Starting the Primed Pump

Start the pump motor with the discharge valve closed and watch pressure gauges, which should show immediate pressure if prime is good. Slowly open the discharge valve while monitoring the priming chamber level and listening for smooth, steady operation.

Signs of Proper Prime:

- Steady pressure readings (no fluctuation)

- Normal motor current

- Smooth sound without air gurgling

- Stable priming chamber level

These indicators confirm your pump is properly primed and ready for normal operation.

How to Monitor and Maintain Prime Daily?

Daily Prime Checks

Your daily inspection routine should cover both visual and performance indicators to catch prime problems early.

Visual Inspection:

- Check priming chamber liquid level

- Look for any liquid leaks around pump

- Verify no air bubbles in system

- Confirm normal pressure readings

Performance Indicators: Performance indicators that show good prime include consistent flow rates, steady pressure display readings, normal motor current, and absence of unusual noises or vibrations. Any changes in these indicators suggest possible prime problems developing.

Warning Signs of Prime Loss:

- Fluctuating pressure readings

- Decreasing flow rates

- Air bubbles in discharge

- Higher than normal motor current

- Gurgling or irregular sounds

Catching these early prevents complete prime loss and expensive repairs.

Weekly Prime Maintenance

Priming Chamber Care:

- Check liquid level and top off if needed

- Test air vent valves for proper operation

- Clean sight glass or level indicators

- Verify chamber connections are tight

System Inspection: Your weekly system check should cover all suction piping connections, signs of air leaks using soapy water to detect small leaks, mechanical seal condition, and strainer cleanliness. These checks delay small problems from becoming major prime loss incidents.

Performance Review: Compare the current week to previous performance, note any changes in operating conditions, check maintenance logs for recurring issues, and plan for any needed repairs before they cause prime loss.

How to Fix Prime Problems Quickly?

When Your Pump Loses Prime Completely

Emergency Response Steps:

- Stop pump immediately (running dry damages equipment)

- Check source tank level – refill if low

- Look for obvious leaks or air entry points

- Verify all valves are in correct positions

Re-Priming Process:

- Fill priming chamber completely

- Open all air vents

- Add liquid until it flows from vents

- Close vents and restart following startup procedure

- Monitor closely for stable operation

This process usually takes 10-15 minutes when done correctly and prevents expensive pump damage.

When Prime is Unstable

Fixing intermittent prime loss often reveals priming chamber size problems. Small chambers can’t handle normal air ingress, so upgrading to larger capacity or considering multiple chambers for large systems often solves the problem.

Common Solutions:

- Increase priming chamber size

- Fix small air leaks systematically

- Improve suction conditions

- Upgrade to better sealing components

Finding air leaks requires systematic checking using soap solution on all connections, inspecting mechanical seals for wear, examining suction piping for cracks, and testing valve sealing.

Prime Maintenance for Different Industries

Chemical Processing Plants

Chemical pumps handling corrosive or dangerous liquids need special prime maintenance attention. These applications require additional safety considerations and specialized equipment.

Daily Checks Must Include:

- Monitor seal flush systems for proper operation

- Check for chemical attack on priming chamber materials

- Verify vapor recovery systems work properly

- Watch for clarity in priming chambers

Special Considerations: Use corrosion-resistant pumps with proper materials, heat priming chambers for melting chemicals, install multiple air removal points, and consider inert gas blanketing for reactive chemicals. These modifications solve chemical-specific prime loss problems.

Food and Pharmaceutical Industries

Clean-in-place systems require modified prime maintenance procedures. Sanitary requirements demand using mechanical seal pumps that prevent infection, designing priming chambers for complete drainage, scheduling prime maintenance during cleaning cycles, and maintaining sterile conditions during prime restoration.

Marine and Port Operations

Centrifugal process pumps and Chemical pump face unique prime challenges from intermittent operation and harsh environments.

Solutions Include:

- Automatic priming systems for remote operation

- Larger priming chambers for extended prime retention

- Non-clogging slurry pumps for clean-up applications

- Backup priming methods for critical services

Marine environments create additional challenges from saltwater corrosion, varying liquid levels, debris in pumped fluids, and limited access for maintenance.

Advanced Prime Maintenance Solutions

Smart Monitoring Systems

Modern monitoring systems provide automatic oversight without manual attention. Key features include continuous level monitoring, automatic alarms, remote smartphone access, and maintenance data logging. These systems prevent pump shutdowns and reduce maintenance costs significantly.

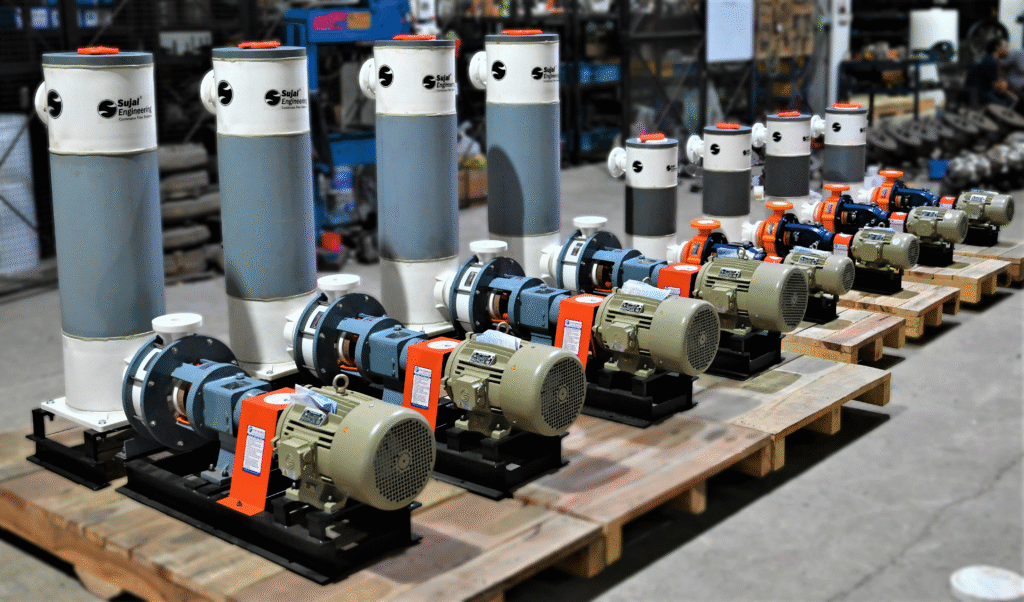

When to Upgrade Your System

Consider self-priming mud pumps, AODD pumps, or liquid ring vacuum systems when facing frequent prime loss, high maintenance costs, or remote operations. Sujal Engineering offers pump repair, overhauling, retrofitting, and spare parts services to upgrade existing systems.

Priming Chamber Sizing Guide

Proper Sizing

Chamber size should equal suction piping volume times two, plus expected air ingress during operating cycles. Key factors include pump flow rate, air ingress rate, duty cycle, and space constraints. Professional sizing from experienced pump manufacturers in India like Sujal Engineering ensures custom pump solutions that work reliably.

Design Essentials

Good chambers include proper baffles, multiple connections, removable covers, and compatible materials.

Cost Benefits and ROI

Real Cost Comparison

Without proper prime maintenance: pump replacements cost $5,000-50,000, downtime costs $1,000-10,000 per incident, plus 20-40% energy waste and production losses.

With proper maintenance: prevent replacements, minimize downtime, maintain normal energy use, and eliminate losses. Systems typically pay for themselves within 6-12 months.

Professional Services

Expert Support

Call professionals for:

- Recurring prime loss problems

- System upgrades and complex designs

- Emergency repairs

Sujal Engineering provides complete evaluations, energy-efficient pumps installation, staff training, and emergency services.

Conclusion:

Proper prime maintenance is simple with consistent procedures prevents major problems.

Key Success Points:

- Verify complete priming before startup

- Monitor chamber levels daily

- Fix air leaks immediately

- Size chambers properly

Whether using thermic fluid pumps, chemical pumps, or polypropylene pumps, proper prime maintenance ensures reliable operation across all industrial applications.

Sujal Engineering provides complete industrial pump solutions including centrifugal process pumps, filter press pumps, and energy-efficient pumps for chemical, textile, marine, and processing industries.

Get Expert Support: Visit www.sujalpumps.com to discuss your prime maintenance challenges and explore our professional services.