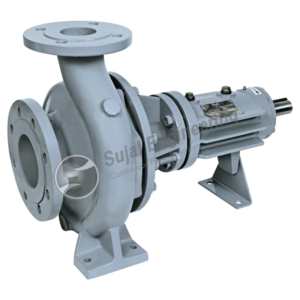

Air Cooled Pumps For Effective Hot Oil Transfer

Air cooled pumps are designed for high pressure and high-temperature applications, providing effective, reliable, efficient and dependable service for industrial needs.

Working Principle

Air cooled pumps isolate liquid in the motor section of the unit for the hot process fluid in the pump casing with a series of pressure ports located in the front bearing housing or pump casing adapter. This isolated liquid is circulated through an air-cooled heat exchanger by an auxiliary impeller located on the rotor assembly. This design allows the motor and bearing environment to be at a much lower temperature than the process fluid, enabling the use of standard bearings and motor insulation significantly reducing both first and long term operating and maintenance costs and eliminates the need for cooling water that could be of poor quality.

Working mechanism

- Design: The pumps are designed to maximize the mechanical seal and ball bearing from the source of heat that constitutes the pump casing, placing between both a thermal barrier and cooling the mechanical seal housing and bearing support by natural convection.

- Pump Casing: The impeller of the air-cooled thermic fluid pumps are a single entry, closed type and dynamically balanced. The impeller has back ring & holes between each fin for the axial balancing of pressures.

- Shaft and Support: The impeller is mounted on the end of the end of the shaft. The shaft is designed to be able to withstand all mechanical and thermal efforts generated during operation of the pump with minimum deflection. The bearing housing is made of cast iron and apart from serving as the shaft support; it also houses the mechanical seal. It is equipped with external cooling wings.

- Shaft Seal & Bearings: Shaft sealing is possible by means of a high-security mechanical seal, placed in the bearing housing, close to the second ball bearing near to the shaft end. The first ball bearing near to the casing is lubricated by pumped liquid. A safety stuffing box with the following throttling area is arranged in front of the first ball bearing and mechanical seal. Even in case of failure of the mechanical seal, these additional safety elements prevent seepage from emerging in a hazardous quantity and manner. The second ball bearing is located near the end of the shaft and lubricated by grease for life.

- Materials used: In order to take the load of hot oil, the pump casing and impeller are manufactured using Cast Iron which is resistant to high temperatures. Stuffing box and bearing housing are made with cast iron (generally GG 26). The shaft is made with high tensile strength material 410 stainless steel.

Salient features of air-cooled pumps

- Standard motor insulation and bearing

- Discharge flange is at top and radial

- Low maintenance

- Centerline supported casing

- Heat resistant mechanical seal

- Bearing environment at lower temperatures

- Eliminates the concern of fouling caused by poor water quality

- Efficient radial multi-vane closed type impeller

- High efficiency

- Flexible bearing option

Application of air-cooled pumps

- Food industries: especially namkeen making plants which use oil for frying

- Petrochemical Industries

- Synthetic – fiber production industries

- Textile, dyeing, printing industries

- Pharmaceutical industries

- Paper and pulp industries

- Timber processing industries

- Cement manufacturing industries

Sujal Engineering has developed a broad range of industrial pumps for various industrial applications. To know more about our product range visit our website: www.sujalpumps.com

Our Air-Cooled Pump is the most premium pumps for transferring hot oil in food industries. To know more about our air cooled pump email us on sujalpumps@gmail.com

Read More:

- Industrial Pumps For High-Temperature Liquids

- Selecting The Right Pump For Food Applications

- High-Quality Food Pumps – A Brief Guide

- Air-Cooled Pumps For Circulating Hot Edible Oil

- Thermic Fluid Pump – Hot Oil Circulating Pump